Screws and fasteners are indispensable in any engineering or assembly project, and different types of screws are suitable for different scenarios as well as needs.Xiamen Huimei Trade And Industry Co., Ltd will lead you to the most suitable high-quality Metal Screws for you in this article.

Knowing the correct classification of Metal Screws can be more effective in use, different screws correspond to different use scenarios, this article will be categorized through the use, structure, surface treatment of different ways:

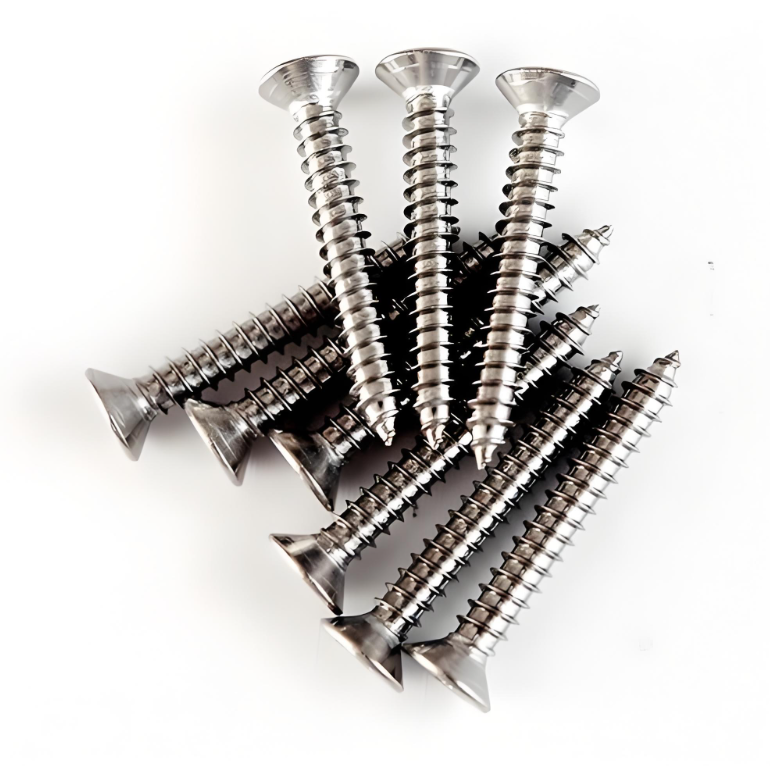

Features: Self-tapping screws are designed with a tip that cuts threads directly into the material, eliminating the need for pre-drilling. They come with threaded ends so the screws can hold the material better.

Uses: Most commonly used for wood, plastic and thin metal joints, especially in the furniture manufacturing and construction industries.

Characteristics: Hexagonal bolts with hexagonal heads are fixed with wrenches or pliers.

Uses: Mainly used in machinery, equipment and construction projects.

Characteristics: The head of flat head screws is designed as a cone, and there will be no bulge on the surface after installation.

Usage: It is more suitable for the installation of the home, and can maintain the beauty.

Characteristics: The head of round head screws is hemispherical, and the contact area of the screws is large, which is suitable for use on softer materials.

Uses: Widely used in plastics, wood and light metals.

Expansion screws: used to provide strong fixings in concrete and brickwork.、

Description: Carbon steel is a common primary material used in the production of Metal Screws and has a high degree of strength and hardness.

Advantages: Relatively inexpensive and easy to work with.

Disadvantages: Prone to rust, especially in wet environments.

Scenarios: Suitable for use in indoor dry environments in furniture, automobiles and building structures.

Description: Stainless steel exhibits excellent corrosion resistance through the addition of alloying elements such as chromium.

Advantages: High temperature and corrosion resistance, smooth appearance.

Disadvantages: Higher cost

Applicable scenes: widely used in outdoor equipment, food processing, medical equipment and chemical equipment.

DESCRIPTION: Alloy steels are enhanced by the addition of a variety of elements and are well suited for extreme conditions of use.

Advantages: Excellent performance in high temperature and high pressure environments, resistant to wear.

Disadvantages: Higher price, usually requires special treatment.

Scenarios: Aerospace, heavy machinery, etc.

Different connection materials will have different screws, such as self-tapping screws suitable for wood, and hexagonal bolts suitable for heavy material connections

According to the use of the environment to choose the right material. Such as will be exposed to moisture or acidic and alkaline environment, it is recommended to choose stainless steel screws. For general indoor use, carbon steel screws are usually sufficient.

The length and diameter of Metal Screws are very important for the strength requirements of the connection. As well as the appropriate size can be effectively avoided due to too large or too small resulting in component damage.

Understanding the classification, material and usage scenarios of Metal Screws, you can make decisions easier. If you have any other questions or need further guidance, please feel free to contact our professional team, we will be happy to provide you with help and advice, so that your every project can be implemented smoothly.