Huimei Industry is a China manufacturer specializing in Sheet Metal Parts Fabrication for 25 years. Whether you need prototype or mass production, from design support, rapid prototyping to volume manufacturing, we have it all. We use laser cutting, bending, welding and other processes to accurately process stainless steel, aluminum, iron and other metal sheets into any complex parts you want.

Huimei Industry can provide you with one-stop customized Sheet Metal Parts Fabrication service. We have established a clear four-step approach: design support-24-hour transparent quotation-sample before production-full visual update. You don't need to be in the factory, you can master every key node with photos and videos. With professional rust-proof packaging and flexible logistics, you just need to wait for the receipt. We have served more than 400 customers worldwide and know how to make remote collaboration work.

|

Material |

Iron/Aluminum/Stainless Steel/Brass |

|

Process |

Stamping, deep drawing, laser cutting, bending, welding, CNC, etc |

|

Service |

OEM & ODM is acceptable |

|

Payment term |

T/T, L/C, Paypal, Western Union, etc |

|

Delivery Time |

7-30Days |

1. Double guarantee of experience and technology

We have been working in rapid sheet metal prototyping for 25 years, and our greatest asset is handling orders for complex, sophisticated and even thorny parts. This means that when you give us drawings or ideas, our engineers can quickly understand your intentions, even anticipate possible problems such as deformation and tolerance control in machining, and give professional advice on optimizing costs and processes.

2. The process is perfect and considerable

We will make a quick sample for you to ensure that the size and function are exactly as expected. Confirm before proceeding to the next steps. During the production process, we take photos or record Short Video for you at key processes (e.g. laser blanking, first piece bending, after welding the finished product), so that you can confirm the progress and quality as if you were in the workshop. This transparent communication completely eliminates the uncertainty of long-distance cooperation.

3. Complete quality control documentation

In addition to strict full size inspection before shipment, we can provide you with Material Certification, First Article Inspection Report, Full Dimensional Inspection Report and other documents. These are not only proof of your receipt, but also a powerful tool for you to prove the quality of your supply chain to your customers.

4. Our professional packaging team ensures all items are protected against rust and scratches during transit. We also offer flexible shipping routes, so you can simply relax at home and wait for your delivery.

What are the advantages of choosing Huimei Sheet Metal Parts Fabrication?

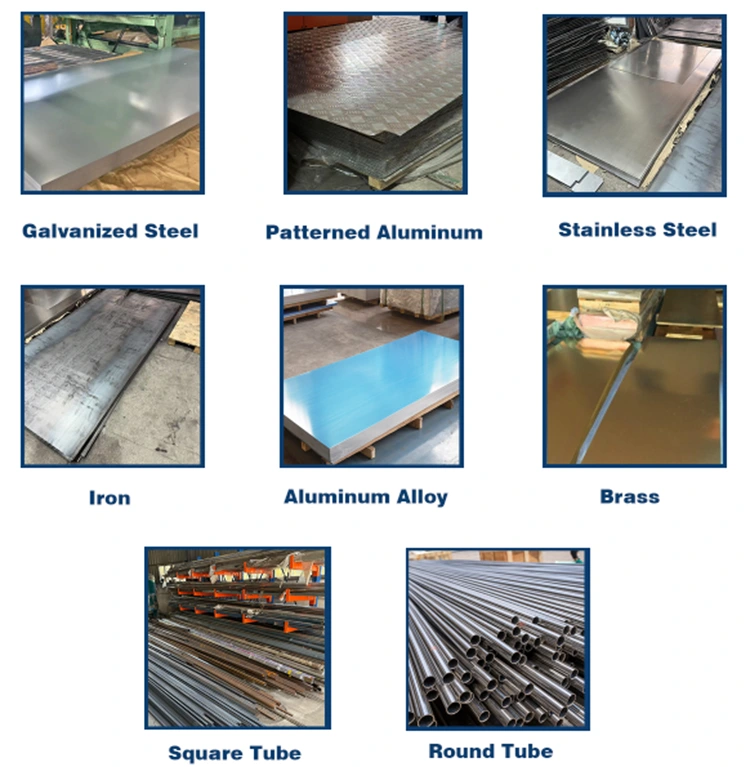

1. Wide range of materials: In Sheet Metal Parts Fabrication, Huim is good at processing stainless steel (304/316 corrosion resistance), carbon steel (best cost performance), aluminum alloy (5052/6061 lightweight preferred) and brass. If you bring your own materials, we also support "processing from supplied materials".

2. Comprehensive process: From laser cutting (thickness in 0.3mm-40mm), precision bending, welding (with tooling fixture and laser welding to reduce deformation), to CNC machining, we have a complete process chain, without your multi-docking.

3. Design support: Even if you only have sketches or physical objects, our team can help you optimize your producible drawings with the goal of saving you comprehensive costs while achieving functionality.

1.Why is there such a big price difference for OEM sheet metal manufacturing from different suppliers?

That’s totally normal! It’s like buying a car — different specs mean different prices. Our quote includes: cost of high-quality materials / precision machining / strict quality control / packaging. We don’t make cheap, low-quality parts.

2.Can you just do the machining if I provide the materials?

Absolutely! That’s what we often call "processing with supplied materials." But we’ll need to check if your material is suitable for our equipment first.

3. What’s the minimum and maximum thickness you can handle?

Laser cutting: from 0.3mm up to 40mm thick. For bending, precision is best under 3mm — anything thicker may require special techniques.

4.

4.Will welding cause deformation? How do you control it?

There can be a little, but we have ways to manage it! We use fixtures to secure parts / weld in sections / apply laser welding to reduce heat impact. Finally, we also do shaping correction to ensure accuracy.