Xiamen Huimei Trade and Industry Co., Ltd. as a customized Sheet Metal Parts processing factory from drawings to prototypes, specializes in producing various metal products such as chassis brackets, shells, chassis skeletons, etc. We support multiple processing services for iron, aluminum, stainless steel, and brass, with precision and speed, from drawings to finished products, providing you with one-stop metal manufacturing solutions.

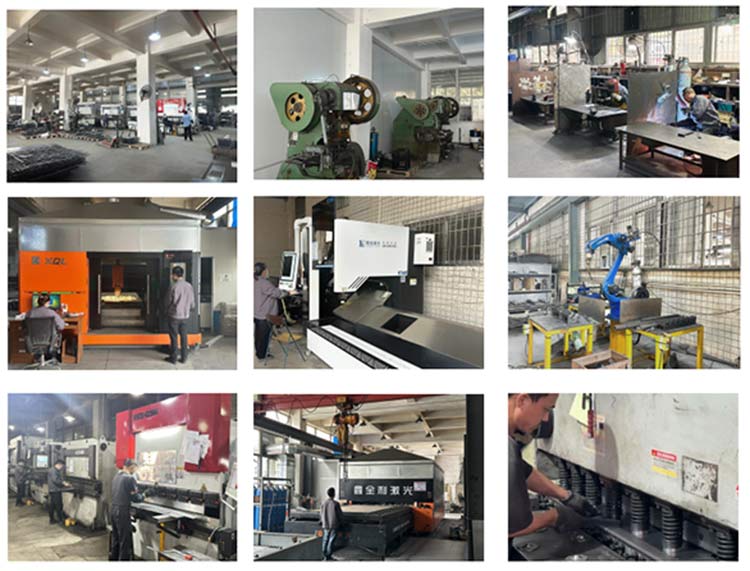

We have 98% of Sheet Metal Parts processing machines, including steel plate and pipe cutting machines, argon arc welding and protective welding, CNC bending machines, stamping machines, riveting machines, and clamping machines.

In terms of surface treatment, we support different processes such as galvanizing, powder coating, electrophoresis, anodizing, chrome plating, etc.

As a professional manufacturer dedicated to producing high-quality Sheet Metal Parts with your creativity, whether you are a small batch prototype or a large-scale production, our high-precision advanced equipment, mature processes, and strict quality control can ensure that every part is accurate and error free.

1. Consultation and quotation: You can provide 2D or 3D drawings (format dwg,. step.) to inform you of the materials, processes, and quantity requirements you need.

2. DFM analysis: Our engineers will provide optimization suggestions and determine the final solution.

3. Order confirmation: We support paying a deposit, and the final payment can be made after the product is completed, or you can pay the full amount.

4. Production and Quality Inspection: We will complete the production within the notified production date and confirm with you at each step, and provide pre shipment quality inspection.

5. Delivery: Deliver on time according to our default packaging or your requirements.

1.Our engineers will review and optimize your drawings for free, reducing costs and improving safety for you

2. Whether you need prototype trial production or a stable supplier for large-scale manufacturing, we can meet your needs

3. At each step, we will measure and ensure that the product size and function meet your requirements

4. Transparent project management, proactive reporting at each critical node, allowing you to keep track of order progress at any time.

Huimei is a professional Precision Custom Sheet Metal manufacturer in China. Whether you need precision shielding for communication equipment, robot skeleton for automation equipment or core support structure for medical instruments, our Precision Custom Sheet Metal tolerance can be controlled within ±0.05mm. This means that our parts are delivered to your production line and can be perfectly assembled without rework, directly improving your assembly efficiency and production stability.

Huimei Industry is a China manufacturer specializing in Sheet Metal Parts Fabrication for 25 years. Whether you need prototype or mass production, from design support, rapid prototyping to volume manufacturing, we have it all. We use laser cutting, bending, welding and other processes to accurately process stainless steel, aluminum, iron and other metal sheets into any complex parts you want.

In China, Xiamen Huimei Industry and Trade Co., Ltd. has over 20 years of manufacturing experience in Automobile Sheet Metal Components in China. Every product we manufacture meets the strength, precision and safety requirements of the automotive industry. If you are looking for it, please contact us in time.

Xiamen Huimei Industry and Trade Co., Ltd. possesses highly stable mold customization sheet metal stamping services. With a fast stamping speed, it can produce dozens or hundreds of parts per minute, reducing your production costs. This mold can eliminate manual production errors and ensure uniform dimensions. You can obtain quotations through our website.